Usually the pre-consolidation of the head of the tunnel excavation, where the soil conditions may cause the collapse of the perforation, GFRP tendons may be utilized with a limited length (3-4 m).

However, there are tunnels where is necessary to make the face improvement by FRP tube with long length tubes in order to avoid deformation movement of the tunnel and the FIT system has been developed to cope with this situation and to be utilized for longer perforations with standard Jumbo drilling equipment.

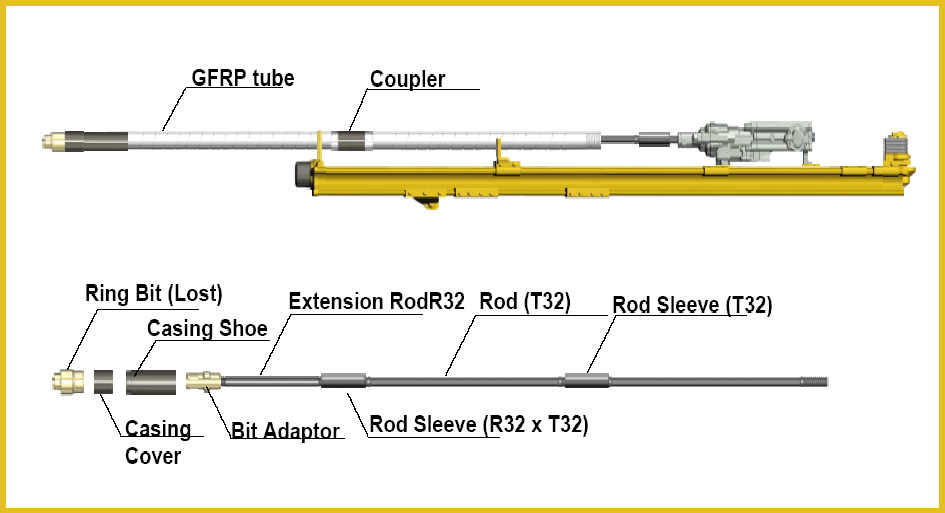

The FIT system (FRP injection tube) is made of a FRP casing with structural capability and a steel driving rod.

Driving Rod and FRP casing will be added up to necessary length, drilled by Drill Jumbo or Crawler Drilling Machine.

The driving rod transfers to the Ring-bit and to the Pilot-bit the rotation and the eventual percussion needed for the perforation, while the FRP casing will be pulled through the hole by the casing shoe without necessity of rotation.

Once the needed depth will be reached, the driving rods and the Pilot-bit will be recovered from the inside of the casing leaving in the ground only the Lose-bit, the casing and the couplers.

This system can then be utilized even in front of the TBM since the metallic parts left in the ground are very limited in dimensions and will be seen by the TBM as simple pieces of rock.

The consolidation injection can then be performed either simply from the open bore entrance connecting to the the FRP casing, or selectively utilizing a hydraulic double packer by means of injection valves previously mounted on the casing.

Download: ATP Fit System for TBM